What is The Comprehensive Production Process of Sublimation Fleece Blanket?

April 6, 2024

Sublimation printing is a popular method used to transfer full-color designs onto a wide range of products, including blankets. Sublimation blankets offer a unique way to create personalized and vibrant designs that are both durable and long-lasting. In this article, we will explore the comprehensive process of sublimation blanket production, from the initial design phase to the finishing touches in a factory setting.

Order Placement:

The process of sublimation blanket production starts with the customer placing an order with the manufacturing factory. Customers can choose from a variety of blanket sizes, materials, designs, and customization options. The factory collects all relevant information from the customer, including design specifications, quantity, delivery date, and any special requirements.

Design and Approval:

Once an order is received, our dedicated design team at the factory springs into action, creating a digital mock-up of the customer’s unique design on the blank blanket. This crucial step not only ensures precision in bringing the customer’s vision to life but also allows them to visualize how the final product will look before it goes into production.

The digital mock-up is then promptly shared with the customer for approval, providing them with the opportunity to make any necessary adjustments or tweak the design according to their preferences. Our goal is to ensure that every custom sublimation blanket is a true reflection of the customer’s style and personality.

Fabric Selection:

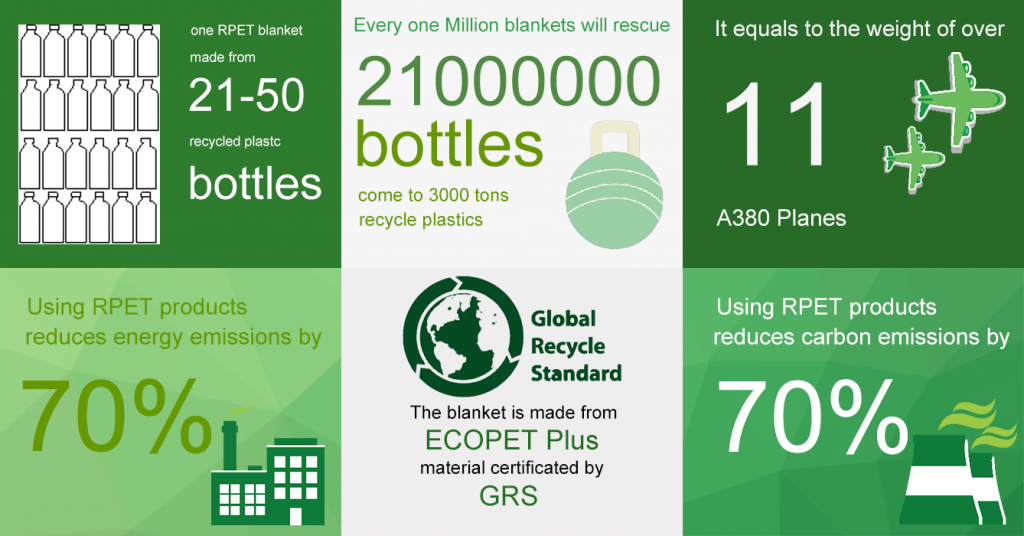

The choice of fabric is a crucial step in the production of sublimation blankets. High-quality materials like polyester are favored in sublimation printing for their excellent color retention and durability. Before proceeding with printing, the selected fabric undergoes a thorough inspection to ensure it meets the standards required for a flawless end product.

Polyester is preferred for sublimation printing due to its unique properties that make it ideal for receiving and retaining the vibrant colors infused during the sublimation process. The fabric’s smooth surface allows for crisp and detailed image reproduction, resulting in stunning and lifelike designs on the blankets. And there are many fabrics to choose from, such as flannel fleece, sherpa fleece, arctic fleece, crushed velvet, etc. You can even add a waterproof layer as a picnic blanket.

During the fabric inspection process, any defects or imperfections such as discolorations, irregularities in the weave, or blemishes are carefully identified and flagged. These flaws, if present, can negatively impact the final print quality and overall aesthetic appeal of the sublimation blanket.

Sublimation Printing:

In the sublimation printing process, our factory employs advanced technologies to bring intricate designs to life using specialized transfer paper and sublimation ink. With a focus on precision and clarity, our team ensures that each design is accurately replicated on the transfer paper. Our expertise in sublimation printing guarantees high-quality results and vibrant colors that accurately reflect the original design.

The next step involves carefully placing the transfer paper onto the fabric before feeding it through a state-of-the-art heat press machine. This machine applies both high temperature and pressure to the fabric and transfer paper, initiating the sublimation process. The sublimation ink on the transfer paper transforms into a gas due to the intense heat, permeating the fibers of the fabric. As the ink cools, it solidifies within the fabric, creating a bond that results in a vibrant and long-lasting image.

Cutting and Sewing:

Following the completion of the sublimation printing process, the printed fabric is ready to be transformed into the desired blanket size and shape. Skilled artisans use precision cutting techniques to carefully trim the fabric to the specified dimensions, ensuring that each piece is uniform and accurate.

Once the fabric pieces are cut to size, the edges are given special attention to achieve a refined and professional finish. This is achieved through a meticulous binding or hemming process, where the edges of the fabric are folded over and secured in place. This not only adds durability to the blanket but also gives it a polished and aesthetically pleasing appearance.

Quality Control and Inspection:

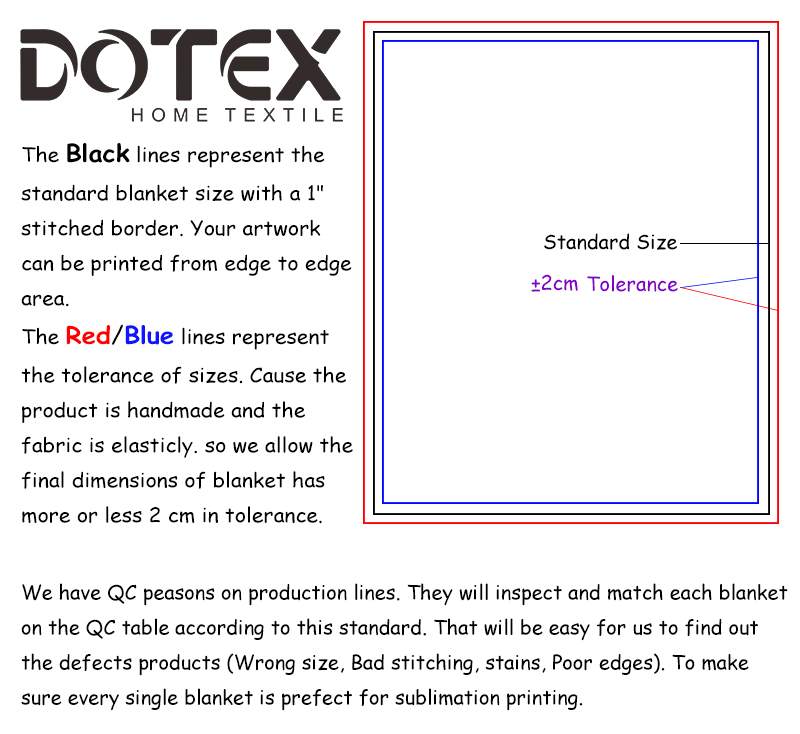

Each finished blanket is thoroughly inspected to confirm every detail for color accuracy, print clarity, and overall quality. Our quality control team meticulously examines each blanket, ensuring that the colors are vibrant, the designs are crisp, and the fabric is flawless throughout.

Fabric quality and general craftsmanship are also meticulously evaluated during the inspection. Our quality control team examines the fabric for any flaws, ensures precise stitching, and checks for overall integrity to uphold our commitment。

Any blankets that do not meet our exacting criteria are either discarded or undergo meticulous reworking to rectify any imperfections.

Shipping and Logistics:

At our factory, we prioritize smooth and reliable shipping and logistics processes to ensure efficient and secure delivery of our high-quality blankets to customers worldwide. Here are the key points of our approach:

- Collaboration with shipping partners: We work closely with reliable carriers and freight forwarders to coordinate efficient and cost-effective transportation methods for each order.

- Order tracking: We utilize advanced shipment tracking systems to monitor the movement of each blanket in real-time, providing customers with accurate and up-to-date information on their orders.

- Secure packaging: We use high-quality materials and techniques to protect blankets from damage during transit, paying meticulous attention to detail in packaging to withstand transportation rigors.

- Eco-friendly practices: We prioritize sustainable packaging solutions, using recyclable and biodegradable materials to minimize environmental impact and contribute to a greener future.

Our factory’s emphasis on efficient shipping and logistics operations enables us to deliver top-quality blankets and exceptional service to our valued clients worldwide.

In conclusion, the production of sublimation blankets is a multi-step process that requires precision, attention to detail, and quality control at every stage. From order placement to delivery, the factory works diligently to create personalized, vibrant, and durable blankets that cater to the unique needs and preferences of each customer. By following a comprehensive production process, the factory can produce high-quality sublimation blankets that leave a lasting impression on customers and set a standard for excellence in the industry.