Blanket Manufacturer: Is DOTEX Leading with Recycled Blankets?

Nov. 6th, 2024

The recycled blanket segment within the textile and home goods markets is flourishing. As consumers become more eco-aware, they are increasingly turning to recycled blankets. This shift in demand has sparked innovation and expansion at DOTEX. The factory relentlessly pursues new techniques and materials to craft high-quality, fashionable, and recycled blankets that cater to meet the demands of sustainable development.

What Are Recycled Blankets?

Recycled blankets, are blankets made from materials that have been repurposed or recycled. Unlike traditional blankets crafted from new, virgin fibers, recycled blankets utilize discarded or waste materials that have been carefully processed to create new, high-quality textiles. This process not only reduces landfill waste but also conserves natural resources and minimizes environmental pollution.

RPET

Bio-Degradable PET

Bio-Degradable PLA

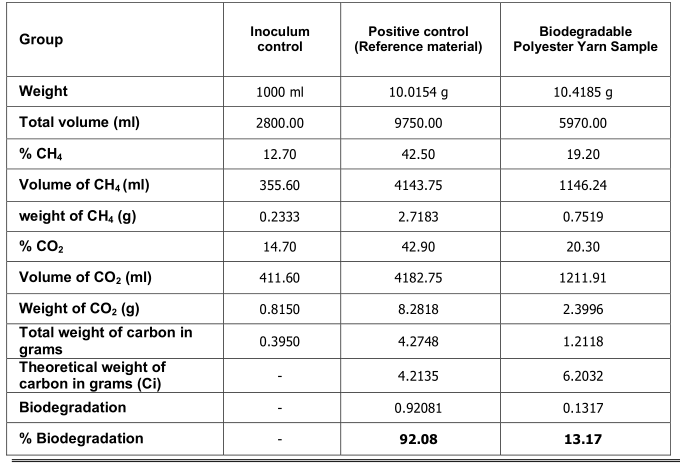

Introduction: "ECO PET PLUS" Bio-degradable PET

- Eco PET Plus offers an end-of-life solution to help these products become more biodegradable, once disposed of in a biologically-active environment.

- with innovative technology, ECO PET PLUS fibre breaks down into simple CO₂ and CH₄ (methane) to reduce textile waste and limit enviromental impact.

- 13.17% biodegradation under ASTM D5511 test standard within 45 days.

- Application: Blanket, Duvet, Napkin, head rest cover…. all soft line products.

Our Recycled Polyester Blanket: Durability Meets Sustainability

Polyester, a versatile and durable fiber, is another common material that finds new life at DOTEX. Our recycled polyester blankets are made from recycled plastic bottles and other polyester-based waste. This process involves collecting the waste, cleaning it thoroughly, converting it into polyester chips, melting the chips down, and spinning it into new, high-quality polyester yarn. The result is a blanket that retains the durability and warmth of virgin polyester but with a significantly reduced environmental footprint.

Collection and Sorting: We initiate our process by actively collecting discarded fleece, polyester materials, as well as recycled plastic bottles from a wide array of sources. These include post-consumer waste, industrial scraps, and even specific recycling programs. Each type of material is meticulously sorted to separate different types of fibers, ensuring that they are properly categorized for subsequent processing.

Cleaning and Processing: The sorted materials then undergo a rigorous and extensive cleaning process. This involves the removal of any impurities, contaminants, and residuals that may have adhered to the materials during their previous uses. This step is vital in ensuring that the final recycled product is not only safe but also of the highest quality possible.

Recycling and Spinning: After undergoing the cleaning process, the materials are meticulously processed further to create brand-new yarn. For fleece, this intricate step often involves carefully re-bonding the fibers to preserve their distinct softness and luxurious texture, ensuring that the recycled fleece yarn retains its original comforting qualities. For polyester, which can include material derived from recycled plastic bottles, the melted plastic undergoes a highly specialized spinning process utilizing cutting-edge textile machinery. This advanced process transforms the melted plastic into high-quality yarn, which is then meticulously prepared and ready for the next production stage, whether it be spinning into fabric or further processing.

These RPET yarn will be meticulously weaved or knitted into a diverse array of fabrics, each boasting unique textures, properties, and potential applications. Whether it’s soft, durable materials perfect for elegant clothing or durable, hardwearing fabrics ideal for robust outdoor gear, the range of fabrics produced is vast and versatile. Furthermore, the entire production process, from the meticulous selection and blending of raw materials at the initial stage of yarn creation to the precise cutting and finishing of the final fabric formation, will be carried out inhouse. This commitment to in-house production ensures rigorous quality control and consistency throughout the entire supply chain, guaranteeing that every yard of fabric meets the highest standards of excellence and satisfies the diverse needs of customers.

Certifications and standards in the industry

GRS certification both for yarn, dye house and home textile facilities

Yarn and final softline products comply to OEKO certificates

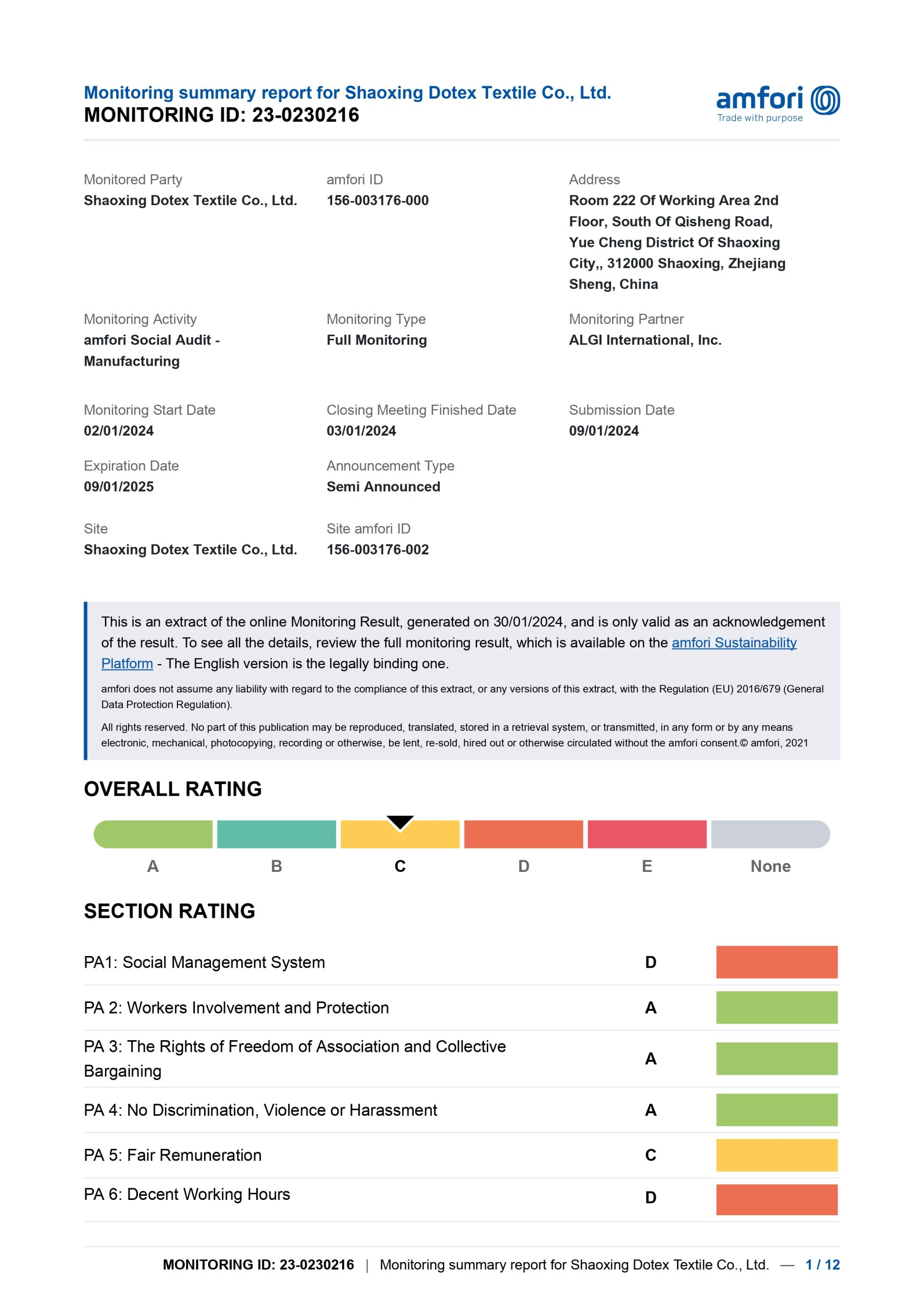

Final softline product factory social compliance audit with BSCI

In conclusion, the importance of sustainable manufacturing cannot be overstated in today’s world, where environmental stewardship and resource conservation are paramount. By embracing sustainable practices, businesses not only mitigate their ecological footprint but also pave the way for a greener, more resilient future. DOTEX Blanket Manufacturer stands as a testament to this commitment, dedicating itself to the principles of sustainability. Through the innovative production of recycled blankets, the company demonstrates that quality and eco-friendliness can indeed coexist. Each recycled blanket crafted by DOTEX signifies a step towards reducing waste, conserving natural resources, and fostering a culture of circular economy. As consumers increasingly seek out eco-conscious products, DOTEX’s dedication to sustainable manufacturing not only aligns with market demands but also sets a benchmark for industry peers to follow.