What is the Important Keys about the blank blanket for Sublimation Printing ?

Competitive Pricing Through Innovation

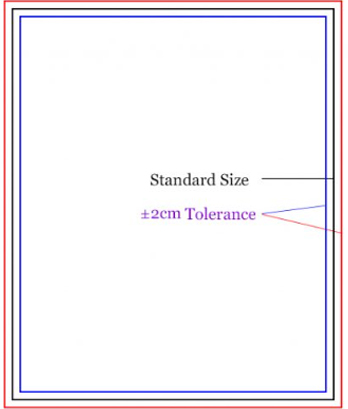

Sublimation printing can be cost-intensive due to imperfections in the size and shape of rubber blankets, increasing production costs. Recognizing this issue, we have invested in automatic cutting and sewing machines to maintain perfect size tolerances. The cost of machine production is lower than manual labor, making our quotes more competitive and advantageous for you.So pls feel free to inquiry us .

Meticulous Packaging for Pristine Products

Our integrated workshop includes neat production, cutting, sewing, quality inspection, transit, and packaging, ensuring our white blankets are not dirtied before boxing. Even after sublimation printing, our blankets maintain their original elasticity and plushness, guaranteeing customer satisfaction.

Uncompromising Quality Standards

Our blankets retain their color and design without distortion, controlling shrinkage within a 1-2 cm range.

Every blanket undergoes rigorous inspection by our quality control team, examining print colors, size, shape, and cleanliness.

We maintain a standard of +/- 2 cm in size error and ensure every blanket is pristine before boxing.

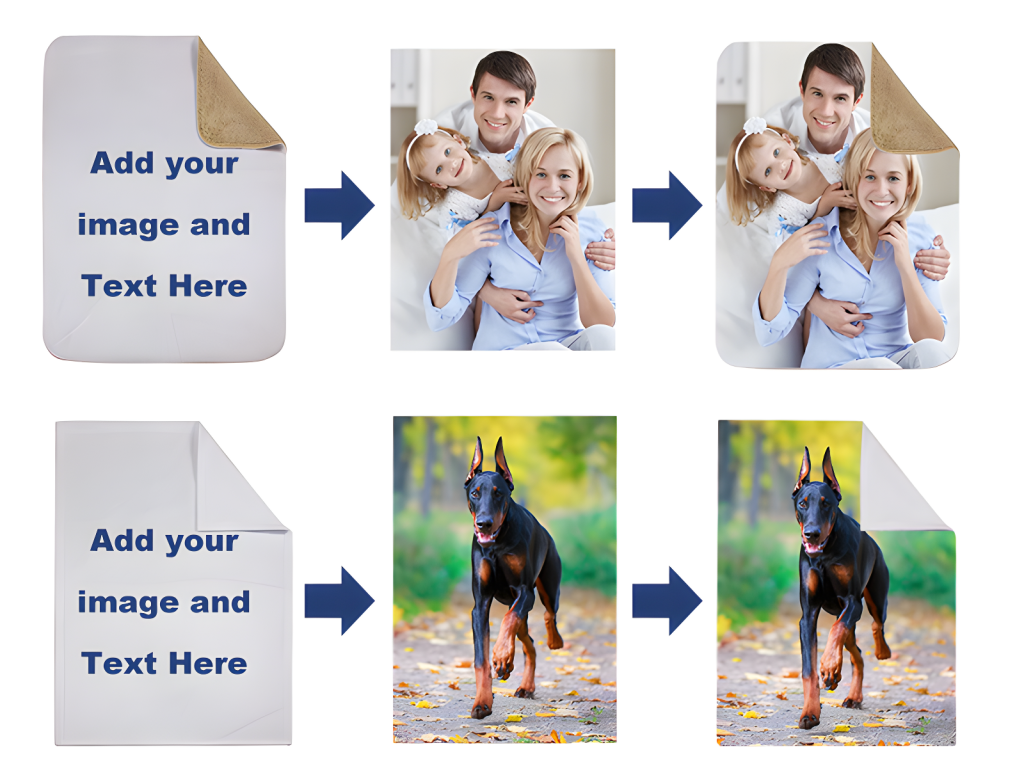

This Video is showing the Heat transfer printing process on the sherpa fleece blanket .The design is printed onto a special heat transfer paper using a printer.The printed transfer paper is placed onto the substrate. A heat press machine is then used to apply heat and pressure. The printed item may undergo additional treatments, such as curing or pressing, to ensure the design adheres properly and is durable.

Overall, heat transfer printing is a versatile and efficient method for creating vibrant and it was goes very good on the fleece blanket